In the ever-evolving landscape of modern manufacturing, CNC (Computer Numerical Control) machining has emerged as a game-changer, redefining the paradigms of product development. This technological marvel blends precision with efficiency, enabling manufacturers to transform raw materials into intricate components with unparalleled accuracy.

Imagine a factory floor where machines hum a meticulous symphony, producing everything from aerospace parts to medical devices, all while adhering to the most stringent quality standards. As industries seek to innovate and streamline processes, CNC machining stands at the forefront, marrying artistry with engineering.

Its versatility not only accelerates prototyping but also allows for the creation of customized solutions tailored to specific needs. In a world where speed and precision are paramount, understanding the role of CNC machining is essential for anyone involved in the manufacturing sector.

The Importance of Precision in Manufacturing

Precision in manufacturing is not merely a technical requirement; it is the cornerstone of quality, reliability, and innovation. CNC machining, with its unparalleled accuracy, allows engineers and designers to translate intricate digital models into tangible products with exquisite detail. Imagine a world where components, crafted with such meticulous precision, seamlessly fit together, eliminating costly reworks and ensuring optimal performance. The ability to maintain tight tolerances fosters a culture of excellence, pushing industries forward and enabling the production of complex geometries that were previously unimaginable. This precision also plays a pivotal role in meeting stringent industry standards, enhancing safety and sustainability while ultimately boosting consumer trust. In an era where even the smallest deviation can lead to significant consequences, the importance of precision in manufacturing cannot be overstated—it is, quite simply, the heart of modern product development.

When considering cnc machine services, the role of precision becomes even more evident. These services are designed to deliver components with exacting tolerances, ensuring that each piece fits perfectly into the larger assembly. The ability of CNC machines to produce parts with such high accuracy reduces the need for post-production adjustments, thereby saving time and resources. This meticulous attention to detail is crucial in industries where reliability and safety are paramount, such as aerospace, automotive, and medical devices. By leveraging CNC machine services, manufacturers can achieve the highest standards of quality, driving innovation and maintaining consumer trust in their products.

Integrating CNC Machining with CAD/CAM Software

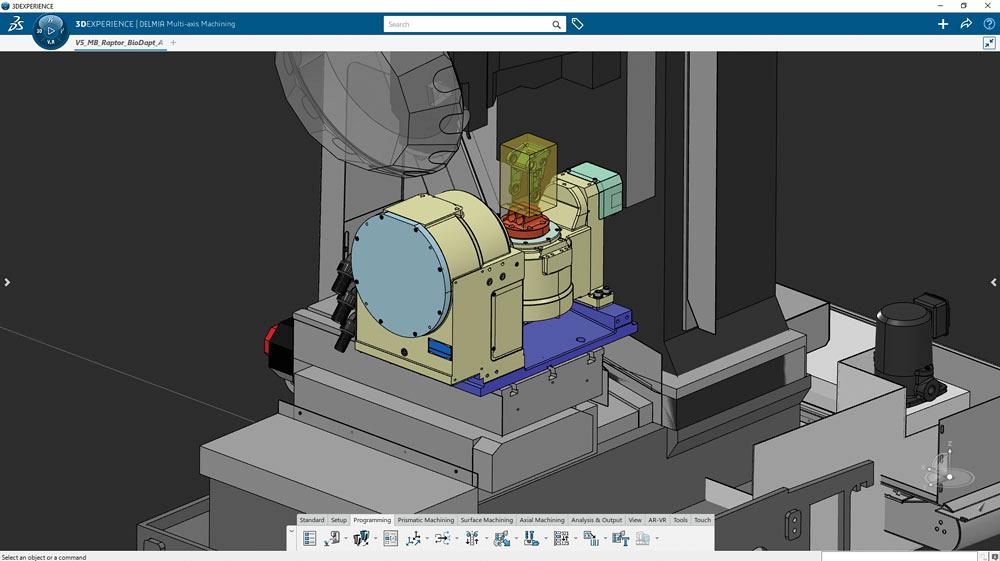

Integrating CNC machining with CAD/CAM software revolutionizes the manufacturing landscape, creating a seamless flow from design to production. By leveraging sophisticated computer-aided design tools, engineers can craft intricate models that push the boundaries of creativity and precision.

Once these designs are finalized, CAM software translates them into actionable instructions, guiding CNC machines with remarkable accuracy. This synergy not only enhances efficiency—minimizing material waste and reducing lead times—but also fosters innovation, enabling manufacturers to rapidly prototype and iterate on designs.

Imagine a world where complex geometries, once deemed impossible, materialize with ease, and the journey from idea to tangible product is transformed into a fluid, swift process. Such advancements underscore the crucial role of this integration in driving modern manufacturing forward, paving the way for products that are both functional and aesthetically striking.

The Future of CNC Machining in Manufacturing

The future of CNC machining in manufacturing is poised to usher in a new era of precision and adaptability. As industries increasingly embrace the Internet of Things (IoT) and artificial intelligence, CNC machines are transforming from mere automated tools into intelligent systems that can predict maintenance needs, optimize production schedules, and customize outputs on-the-fly.

Imagine a factory floor where machines communicate seamlessly with each other, adjusting parameters in real-time to meet shifting demands or unexpected challenges. Furthermore, advancements in materials science promise a greater range of machinable substances, pushing boundaries that were once thought inviolable.

In this rapidly evolving landscape, manufacturers who harness the capabilities of CNC machining not only gain a competitive edge but also pave the way for innovative product development that meets the needs of a more conscientious consumer base. Indeed, the horizon gleams with promise; the intersection of technology and craftsmanship is set to redefine what is possible in manufacturing, turning visionary ideas into tangible reality.

Conclusion

In conclusion, CNC machining has become an indispensable part of modern manufacturing and product development, driving efficiency, precision, and innovation across various industries. Its ability to create complex designs with minimal human intervention not only accelerates production times but also enhances the quality of the final products.

As companies continue to adopt advanced CNC machine services, the role of this technology will only grow, enabling businesses to meet the increasing demands of todays market while maintaining competitiveness. The future of manufacturing is undoubtedly intertwined with CNC machining, paving the way for smarter, more efficient, and highly adaptable production methods.